In today’s competitive landscape, industries strive for excellence in producing top-quality, safe, durable, and cost-effective products. Beyond physical manufacturing, significant resources are dedicated to concept studies and simulations. Virtual prototyping with multi-scale simulation throughout the product development cycle addresses this fierce competition effectively.

The global industry is increasingly shifting towards hybrid and electric vehicles (EVs), where batteries play a crucial role. Unlike their previous role in powering portable electronics, today’s batteries endure more severe conditions and are growing.

As integral components of EVs, batteries face challenges such as extreme temperatures, transportation stresses, and complex charge-discharge cycles. Their evolving role in storing higher energy capacities brings heightened risks and demands rigorous design and testing protocols.

Benefits

Maximum Range

Build To Operate Co-Design To Target Passenger Experience Engineered To Fly

Enhance Safety

Thorough simulations and analysis help keep safety standards by predicting and fixing potential problems before they happen, ensuring reliable performance in different situations.

Optimize Energy Storage

Designers can reach the best energy storage capacity by understanding battery aging, temperature effects, and electrical performance, which helps improve efficiency and extend battery life.

Improve Battery Materials

Chemical analysis tools assist in developing better battery materials, which leads to improved performance, longer battery life, and increased efficiency in a variety of applications and uses.

What We Offer?

Minimize Part Weight and Reduce Cost using Lightweight Engineering Solution

The 3DEXPERIENCE platform from Dassault Systèmes provides a comprehensive PLM solution offering diverse roles, enhanced capabilities, and decision-making tools for designers, engineers, and analysts. Users benefit from seamless connectivity, collaborative tools, and insights into project analytics, simulation outcomes, project statuses, and decisions.

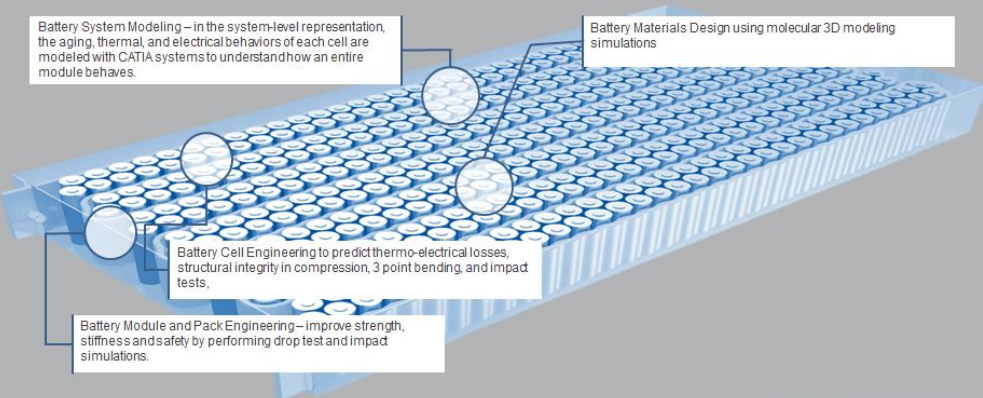

By utilizing 3DEXPERIENCE SIMULIA Abaqus and Isight, a unified battery cell model is created to optimize material parameters and align them with experimental data. Isight functions as a parametric optimizer and automation tool, streamlining the process of data matching with Abaqus through specific workflows and components. This approach ensures the jelly roll material model adjusts to factors like strain, strain-rate, and state of charge (SOC). The resulting homogenized model, significantly scaled down using Abaqus and Isight, reduces the numerical battery model size by a factor of 200.

With the reduced numerical battery model, efficient studies, and analyses such as static analysis, vibration analysis, system random response, and dynamic drop tests can be conducted.

-

- Comprehensive PLM Solution: 3DEXPERIENCE platform integrates diverse roles and enhanced capabilities for decision makers, designers, engineers, and analysts.

- Seamless Connectivity: Enables collaboration and insight into project analytics, simulation results, and project decisions.

- Unified Battery Cell Model: Created using 3DEXPERIENCE SIMULIA Abaqus and Isight to optimize material parameters and align with experimental data.

- Efficiency in Analysis: Drastically reduces numerical battery model size by a factor of 200, facilitating various studies and analyses such as static analysis, vibration analysis, and dynamic drop tests.

Do you want to Implement SIMULIA?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat.