EDST e-Learning is an online learning initiative by EDS Technologies leveraging 25 years of industry experience as the largest Engineering and Enterprise Solutions company in India. The online courses are curated by industry experts and academic subject-matter leaders.

EDST Technologies is a Certified Education Partner to Dassault Systèmes and an authorized Academic Partner to Autodesk ensuring certified industry-specific programs enabled through these partnerships. EDS Technologies has developed training programs tailor-made for students, beginners and advanced users in Automotive, Aerospace, Industrial Equipment, AEC and other industries. It has trained more than 60 thousand users and has experience of 6 million training hours in the last 25 years.

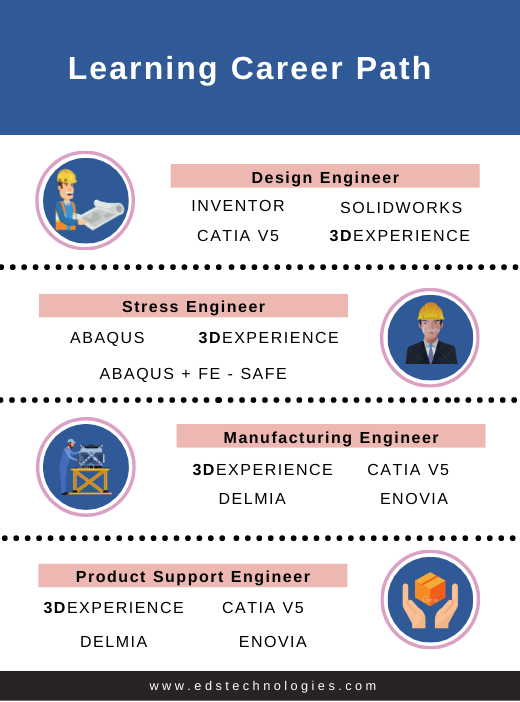

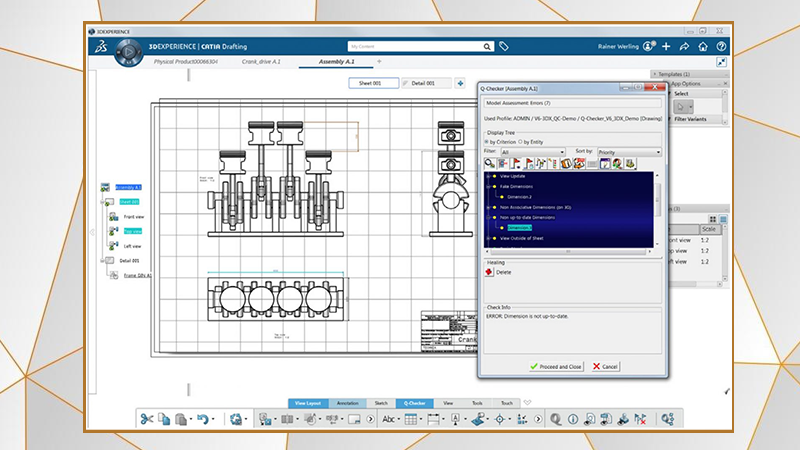

EDST Technologies capitalized years of experience in training and launched online learning platform EDST e-Learning. It specializes in Mechanical Engineering, Civil Engineering, and Industry based skills courses. Courses are meticulously curated by a team of industry experts and academicians. Currently, e-learning courses range from Product Design, Domain Courses, Industry CAD applications such as CATIA, AutoCAD, Solidworks Inventor, and Revit and is extensively working on launching new courses.

The industry is amidst the Industry 4.0 revolution and it is going to transform the workplace through technology innovations such as Artificial Intelligence, Cognitive Automation, Advanced Analytics Internet of Things and Advanced Robotics. As per Deloitte Consulting, there will be 4.6M manufacturing jobs to fill from 2018–2028 however skill gap may leave an estimated 2.4 million positions unfilled. EDST e-Learning’s vision is to bridge this skill gap and upskill the workforce of the future.