Typically, in a manufacturing organization, after the design stage and before manufacturing, there is a stage involving planning/PPC and manufacturing engineering. DELMIA (Digital Enterprise Lean Manufacturing Interactive Application) helps organizations to do feasibility study and process validations during detailed process planning immediately after the design stage.

Below are three DELMIA digital manufacturing solutions which can be used in the day-to-day workings of a Simulation Engineer to plan and manufacture.

- Assembly Simulation

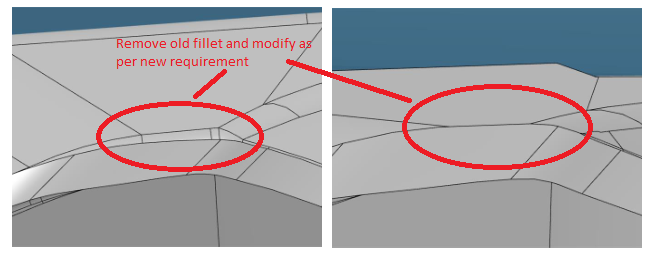

While planning for assembly processes, one always needs to take care of feasibility for fitting and disassembly sequence for maintenance purposes. Many organizations perform study on the actual part or the prototype which is expensive and time-consuming. Also, multiple iterations are involved in the study as it is in later stages of design.

To avoid these challenges, planners can use virtual tools like Assembly Simulation and simulate the assembly and disassembly sequences and check for multiple possibilities. By doing this, they can validate the assemblies for static and dynamic clash, ease of doing maintenance, tool accessibility etc.

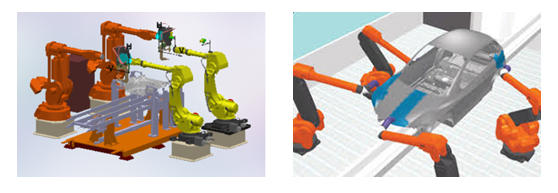

- Robotics

Many organizations use robots for speed, repeatability and accuracy of work or in hazardous environments like welding. Robot programming with technical support for a particular task is a tedious job and it takes the production time of the robot which is expensive due to loss of productivity.

With DELMIA Robotics, one can teach the robot in the virtual world for welding, material handling, painting, machining, shot peening etc. After validating the program, one can transfer it to the actual robot. After some minor corrections, the robot will work as needed. Hence, the organization can save time and money by using these robots as they can work uninterrupted for a long time.

- Ergonomics

- Ergonomics of the shop floor for comfort and safety of the worker.

- Product ergonomics for consumer experience.

There are two aspects in ergonomics:

At times organizations do ergonomics study by producing expensive prototypes or apply their learnings from previous experiences. Many times one can observe that workers are not productive because of the work environment. Due to this, there is a productivity loss to the company.

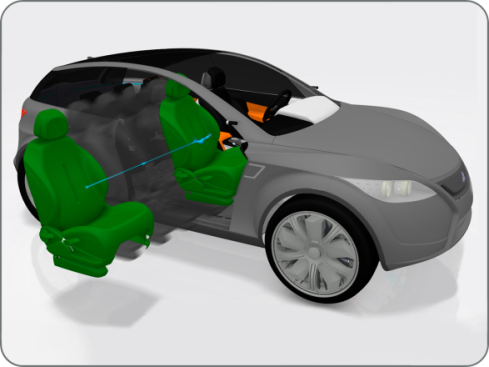

Using virtual validation of ergonomics, one can improve the work experience of the worker as well as enhance consumer experience. Ergonomics study is useful to ensure comfort, ease of use, reduce fatigue and ensure more productivity. By checking the feasibility and reachability, one can ensure safety and reduction in stress level of the user.

DELMIA’s ergonomics solutions can help you to do interior design of automobiles and airplanes, work safety analysis and maintenance tasks.