“Cloud” has been the buzzword for the past few years. Many companies have identified the upcoming business needs and challenges and have adapted by shifting to On-Cloud solutions. Decision makers need to be always connected digitally with the respective stakeholders.

The main conundrum now is that how can design and manufacturing be connected through cloud. Based on interactions with customers, some of the challenges perceived by them are listed below:

- How can digital continuity be maintained from RFQ to marketing and sales?

- How to connect service providers and respective stakeholders all the time by maintaining the same data connectivity?

- How to perform design, reviews, manage projects, conduct live digital meetings and so on?

Below are the 10 ways how the adoption of 3DEXPERIENCE On Cloud from Dassault Systèmes has helped customers tackle these challenges and maintain the digital continuity.

- 3DEXPERIENCE On Cloud provides a holistic real-time visibility of business to all stakeholders connecting people, ideas, data and solutions in a single collaborative and interactive environment.

- Cloud enables everyone involved in the project to interact, imagine, design, simulate and deliver.

- With the help of Cloud, collecting, importing and sharing project data can be done immediately to the respective team. Data can be stored in 3DSpace, a centralized server of Dassault Systèmes maintained by Amazon Web Services.

- Assigning and managing tasks or projects between different stakeholders and tracking the projects through web can be done by Cloud.

- Design reviews can be done on the fly irrespective of the location.

- Using Market Place and Part Supply accessibility, order can be sent to the certified suppliers or vendors.

- The Cloud solution is cost effective and provides immediate access to users.

- Cloud is adaptable, flexible and scalable with automatic updates.

- It enables faster collaboration by enabling accessibility anywhere, anytime and on any device.

- It is secure with protected environment.

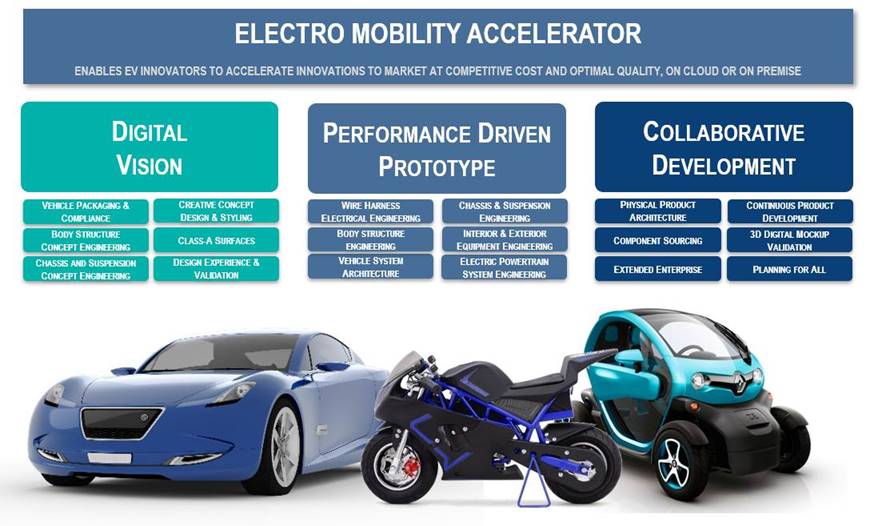

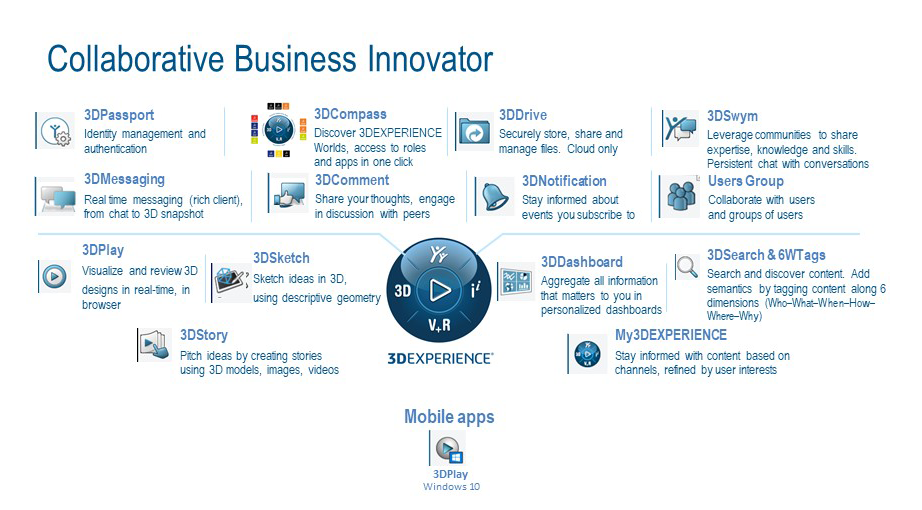

The cloud-based 3DEXPERIENCE platform provides access to a growing portfolio of solutions that work together seamlessly. Some of them are discussed below in detail:

- Collaborative Business Innovator

- Express innovative and creative ideas with communities seamlessly.

- Digital connect with live dashboards assists in collaboration.

- Can sketch and share ideas on the fly with the help of this solution.

- Instant contribution makes the discussion more interactive and expedites decision making.

- Project Planner

- Collaborative project planning with real time KPI monitoring.

- Assign tasks to the respective users with deadlines and tracking the same with seamless integration.

- Project planner dashboard can be accessed through mobiles, iPad and PCs anywhere anytime.

- 3D Innovator

- Can do web based parametric design which helps to design anywhere, anytime and on any device.

- Design and assemble parts, design guidance for topology, non-parametric optimization and accesibility to marketplace to 3D print the components.

- Can manage complete PLM which improves efficiency, quality, productivity and innovation

- Lean Team Player

Manufacturing teams can conduct digital meetings, track with the inbuilt lean principles with virtual models, process and resources