Innovation is very vital for the growth of any company. Anticipating and meeting the needs of consumer creates consumer trust and brand value. Behind a successful brand, there is a team of many individuals contributing with their expertise. However, these efforts from the team members are more often fragmented and results in lower performance and profitability.

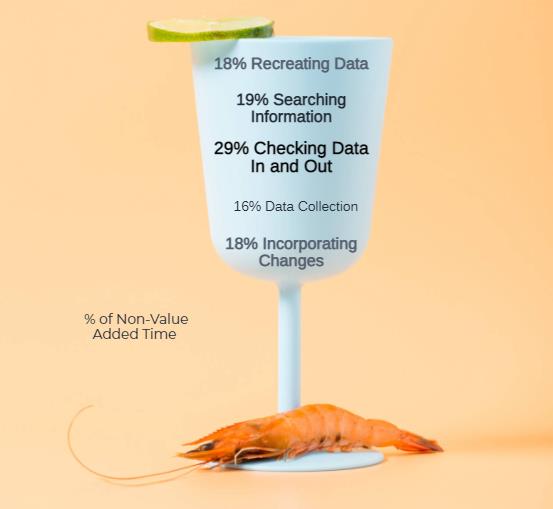

Individual departments perform tasks in silos and miss out on connecting with the other departments, which leads to a lot of non-value-added time.

The food & beverage industry, in particular, is facing the below challenges:

- Coping up with health & wellness trends – There is a surge in demand for healthier products in the times of COVID-19. For companies, it has become a mandate to expand and modify the existing portfolios to support the demand for products that are natural, botanical & contain plant-based proteins. The formulation needs to be altered as the focus has changed from food to nutrition. Reduction of added salt, sugar, and fats is a must, and there is a need to come up with foods that nourish each body type.

- Ever changing consumer behaviour – The recent trends like an inclination towards Hyper-Local food and alcohol-free beverages are here to stay. Consumers are looking for new ways to engage with brands and aspire for products that could reflect their unique identity. Market needs are shifting faster than ever before, and companies must adapt quickly to deliver meaningful innovation as per the changing consumer preferences.

- Pressure of earning profits – There is growing pressure from investors to drive sustainable growth and increase profits. Also, the pressure of rising commodity and resources cost needs to be managed. Fragmented IT infrastructure and declining IT budgets are forcing companies to look for more efficient solutions.

- Production getting complex – Demand for more personalized products is leading to an increase in SKUs. Also, there is a pressure of coming up with new assortments with more channels to serve. Managing production complexity to provide the right product at the right time is critical.

However, not all companies have the means & resources to manage these challenges in the most efficient way. It is high time for food & beverage companies to adopt the “digitalization” for product development to take innovation and profits to the next level.

The benefits of going digital in the food & beverage industry are as described below:

Seamless Collaboration – In the food and beverage industry, the multiple teams need to collaborate to bring new ideas, products and artwork to market. Gone are the days when companies could afford the inefficiencies and losing market opportunities from disjointed product data. The need of the hour is to tie product innovation, development and commercialization processes together with a holistic platform that provides multiple applications for continuity and connectivity of information, people, and processes.

Developing a successful product that excites consumers requires an integrated approach across formula, packaging and labelling design. Unfortunately, most companies support the development process with a patchwork of point solutions that are stitched together but not integrated, resulting in poor efficiency, product launch delays, and missed customer expectations.

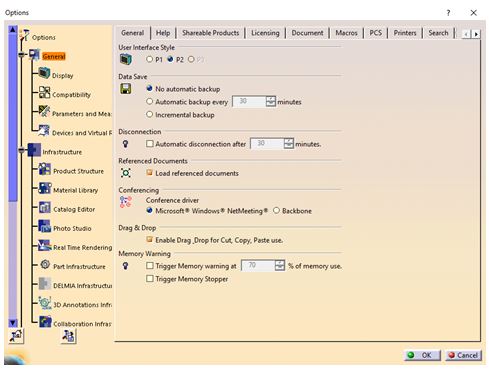

For an organization to manage its work smoothly, the disconnect between departments needs to be dealt with so that everyone has access to accurate and updated information in real-time on a single platform.

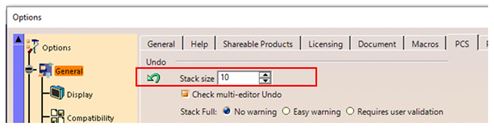

Integrated Project Management & Clear Business Dashboards – Launching a new product to market is as fast as your slowest link is. Typically, the project managers who are deprived of the right system need to refer multiple systems and manually collect and collate project statuses from different stakeholders. With the adoption of an integrated project management capability tool, project managers can focus on actual project management activities like evaluating the project progress, identifying and reducing risks, and aligning resources to maintain or accelerate schedules.

When project statistics, assigned tasks, dependencies, risks status, timelines, financials, meeting minutes are all contained on a platform with established processes, managers can improve project execution and performance.

Competing for new opportunities and growing faster than competitors requires real-time data and the insights it provides. Companies are pursuing greater speed, scale, and simplicity across every area of their operations. Real-time data is the catalyst making these three goals and many others possible to achieve.

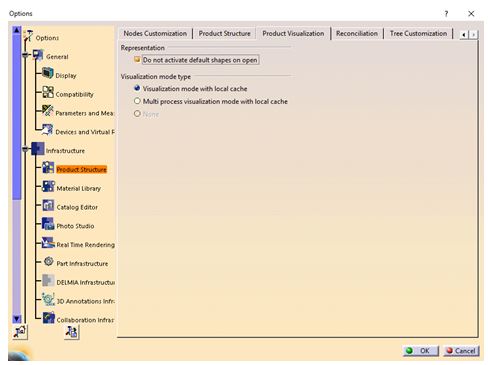

Immersive Virtual Reality – The need of the hour is to enable food & beverage companies to create high-end visualizations for interactive marketing and sales experiences. It is required to quickly create unique products, digital assets, images and videos to engage the customers with interactive and personalized product experiences. The companies also need to virtually bring together Brand Manufacturers, Artwork Studios, Agencies and Packaging Suppliers to accelerate breakthrough designs. With this, companies can shorten package design cycles, reduce costs, lower the possibility for production issues and virtually eliminate recalls.

The era of static 2D planograms is nearing its end. By realistically simulating immersive, lifelike 3D store environments, food & beverage product brands and retailers can better imagine, validate and deploy winning shopping experiences while increasing product appeal, in-store execution, compliance, brand & category profitability and equity all while setting themselves apart from the competition.

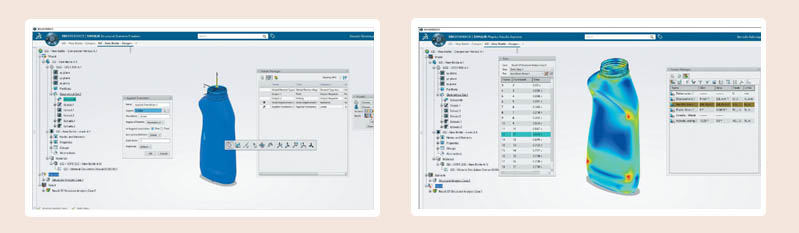

Eliminate the Prototyping – In the modern design era, leading digital tools introduce modeling and simulation into the design. These tools enable innovators to focus on developing the ideal solution for the consumer. Automating the impact analysis of design decisions gives them the ability to iterate more freely.

To create better product and package designs, expensive prototyping can be eliminated through modelling and simulation. By using digital tools, identifying and eliminating mistakes in the digital stage is done, when changes are least expensive. Companies can digitally model and simulate the product, before committing a dime in the physical world.

To sum up, food & beverage companies need to adopt digital solutions to take innovation and profits to the next level. All the key stakeholders in an organization need to be empowered to make the right decisions by having access to the project insights. These insights must be made available in real-time so that it can be used effectively by the stakeholders of the organization. Informed decisions are always better than snap decisions.