Quality Control (QC) is a vital process in product development that guarantees defect-free products to customers. Ideally, product design and development is done with the perfect flow of data between different teams, departments, and companies with reduced cycle times. Manufacturers are always under pressure to produce a large volume of products in a shorter cycle leading to rushed quality checks.

The common issues in product data quality are incurred by errors and discrepancies in:

- Norms and Standards in layers, naming conventions, parameters, start model, and drafting conventions.

- Geometric continuity of leaks, holes, standard rotation, tiny edges, and duplicate entities.

- Methods for functional tolerance annotations (FT/A), model links, feature order, and specification tree order.

If Quality Control is not implemented successfully, the business is at risk with their customers. For example, the recent case of defects in the airbags of a Japanese Global Automotive Parts Company resulted in one of the most significant automotive product recalls. The automotive company had to recall 69 million airbags valued at billions of dollars.

Successful implementation of quality control is important yet tricky. Quality checks are often done at the end of the production process, detecting the product issues after the fact. However, effective quality control includes two levels:

- Engineers identify and address the errors and issues in the product design right away.

- Operators observe the manufacturing process to ensure there are no variations in the product data.

Manual Quality Check is time-consuming and prone to human errors. Implementing the use of modern digital systems helps in optimizing quality control to produce error-free products efficiently. Q-checker is one such digital quality control tool that helps manufacturers to produce error-free final products.

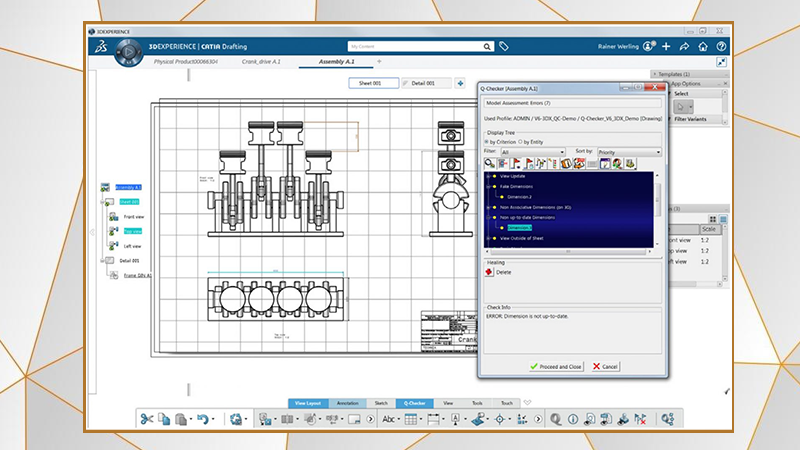

Q-Checker is a Product Data Quality (PDQ) management application that ensures company design standards and specifications adherence within CATIA throughout the digital manufacturing process. Q-Checker is the world’s leading system for quality assurance in digital manufacturing developed by Technia. It enforces efficiency, productivity, and high product quality in the digital design and production processes.

Q-Checker is an add-on module integrated into CATIA V5 that checks the product data quality and provides a verified check seal for final product data. This check seal stores the model results with high security and enhances internal collaboration with suppliers. This seal saves the time of the follow-up teams by eliminating the need for parts checking to ensure product accuracy and quality.

The functions of Q-Checker are implemented on CAD models in interactive and batch mode to check CATProducts, CATParts, and CATDrawings. The profile editor establishes the criteria that the CAD models are checked for in the design process. The check profile has 400+ checks available, and it is possible to configure new checks with the profile editor as per user requirements for each OEM, project, process, and product.

The Q-checker profile consists of a series of files and folders that define which examinations are to be executed with which options. These files are viewed and edited in the check profile editor. A useful advantage of Q-Checker is the automatic heal option for 50% of the standard checks that help with the automation of the check and correction of parameters.

Key Features of Q-Checker:

- Enforce CATIA standards: It ensures the company design standards adherence during the design process in a CATIA V5 system that helps in improved product quality, productivity and efficiency.

- Establish Supplier Trust: Product design and development involves multiple suppliers sending their product data. Using Q-Checker throughout the OEM, the quality of the product data sent by a supplier possess a verified Check Seal, and the recipient can trust the supplier to send quality product data. Also, suppliers can assure the delivery of quality models within the confines of the design standard to their partners and customers.

- Check files from other CAD software: CATIA users often use various CAD systems that create a problem in data translation and calls for redesign and rework. Q-Checker helps to check errors and make necessary adjustments for smooth data transfer.

Advantages of Q-Checker:

- Saves Time spent on Corrections: Correcting the errors and mistakes in CAD models is not only takes consuming but also requires human labor and materials. The need for these corrections is eliminated by using Q-Checker. It identifies and repairs critical errors in product design that would be indistinct to the human eye.

- Encourage Design Reuse: Most designers prefer rebuilding a new model instead of using an existing one as model errors are common with traditional designs. However, with Q-checker, the final designs are error-free, encouraging designers to reuse model designs that save the time of designers as starting from scratch on a new model is time-consuming.

- Pro-active Learning: Using Q-Checker is like having the experience and advice of experts at hand that is especially helpful for new and learning designers. It helps these new designers going through the learning curve with the ability to meet the CAD standards expected by the customers.