In the competitive world of business, quality has been & remains to be a necessity. Quality failures can result in bringing down a business reputation quickly and comprehensively and that leads to the introduction of new products or any significant changes to existing ones, which is a particularly delicate process.

The dynamic business environment, including volume growth and increasing quality expectations, however, has made major players in the Automotive / A&D industry to rethink their strategies. The industry has decided to take the lessons learned from their experiences and adapt methodologies & technologies to address the issues.

Advanced Product Quality Planning (APQP) was developed in the automotive industry to follow certain procedures and techniques and is also typically required to be audited and registered to IATF 16949. This methodology is now being used in other manufacturing sectors as well and has relevance to the successful planning, production, and release of just about any product.

APQP provides structure to the product development process in a manner that ensures customer satisfaction by planning and scheduling the tasks to be done, monitoring the timely and effective completion of tasks, and communicating, escalating, and resolving issues. In essence, APQP combines project management with the use of proactive product development tools applied at the right time.

Now the challenge is to identify a system that delivers APQP in an effective & systematic way that the industries can utilize for sustainable growth & stay ahead of the competition.

With the demand for technology & system comes the need for automation across all disciplines right from the change in design to the downstream department where these changes should be automatically notified and updated across all associated documents like Process design, PFMEA, DFMEA, and PPAP value chain. The stakeholders want a robust system with no or minimal manual intervention to avoid manual errors, manipulation, and hence automate the process right across.

Customization

With the increased demand for automation, many solution providers are enhancing the OOTB functionalities through customization to bring this automation as per customer needs as ready-made packages/bundles.

Customization capabilities are playing an important role in decision making of the solution to suit the needs of every customer when it comes to APQP process mapping.

Custom program development tools/utility available as part of the system enables these customizations for every customer’s needs/automation, of course, with the help of expert consultants who are available in the market for all such expectations.

Majority of the functionalities are available as OOTB. However certain capabilities need to be customized as per requirements using the custom tools & utilities available within it.

Many solutions are available in the market to address these requirements. However, choosing the right solution that has platform capabilities, scalability and that can address diverse requirements right from design, analysis, manufacturing, quality to downstream departments is a smart & intelligence choice in terms of ROI and on a long-term business benefit.

Dassault Systemes’ 3DEXPERIENCE Platform offers solutions to map APQP methodologies covering all of its phases for any customer who is compliant & adhering to IATF 16949 or AS 9145 standards.

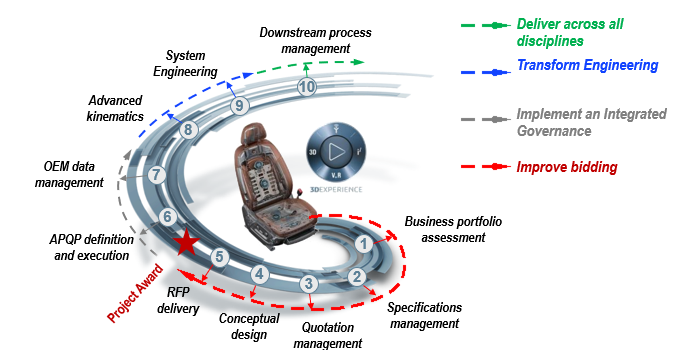

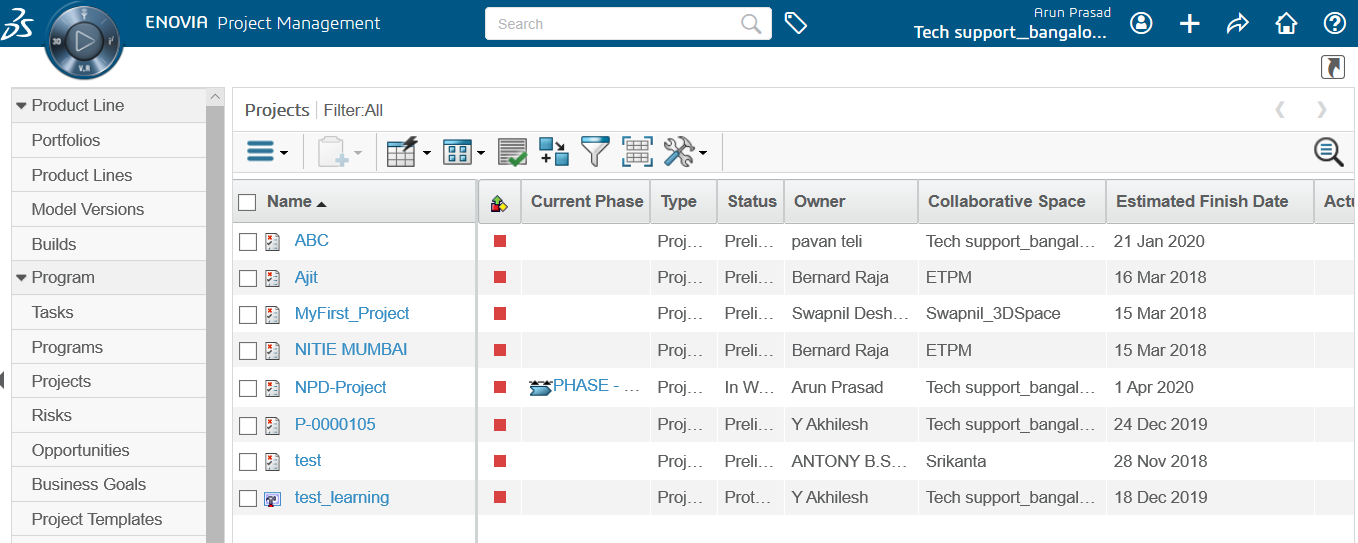

3DEXPERIENCE’s RFx & Project Management solution addresses the APQP requirement right from the conceptual stage to the delivery of components to its destination as shown below.

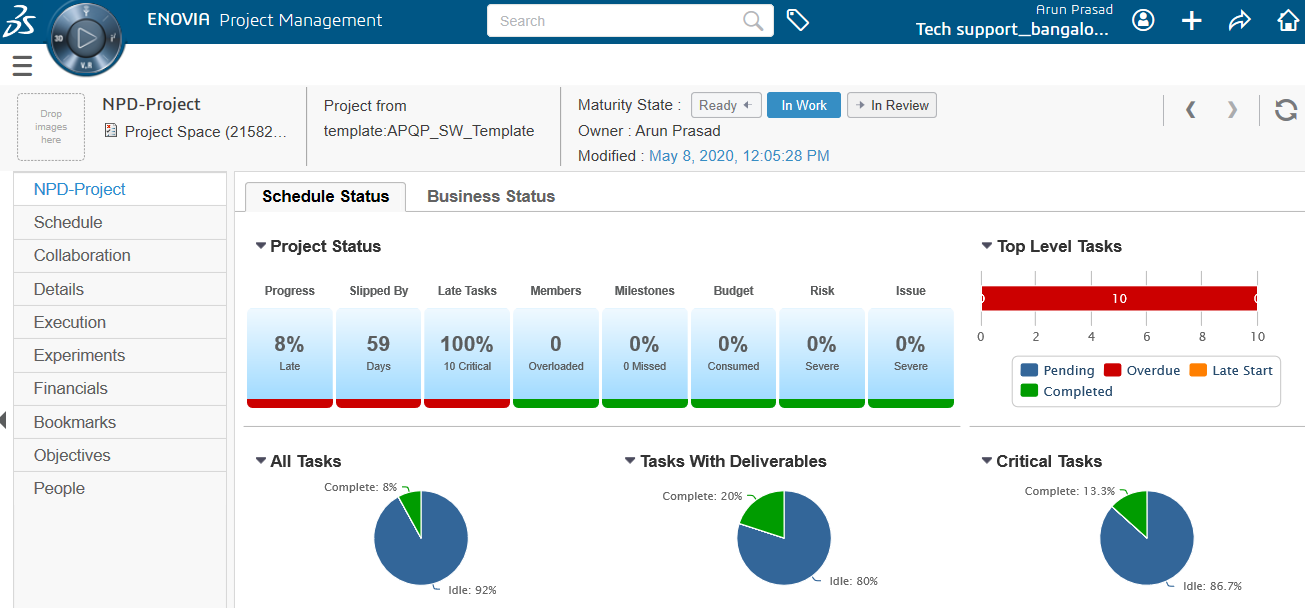

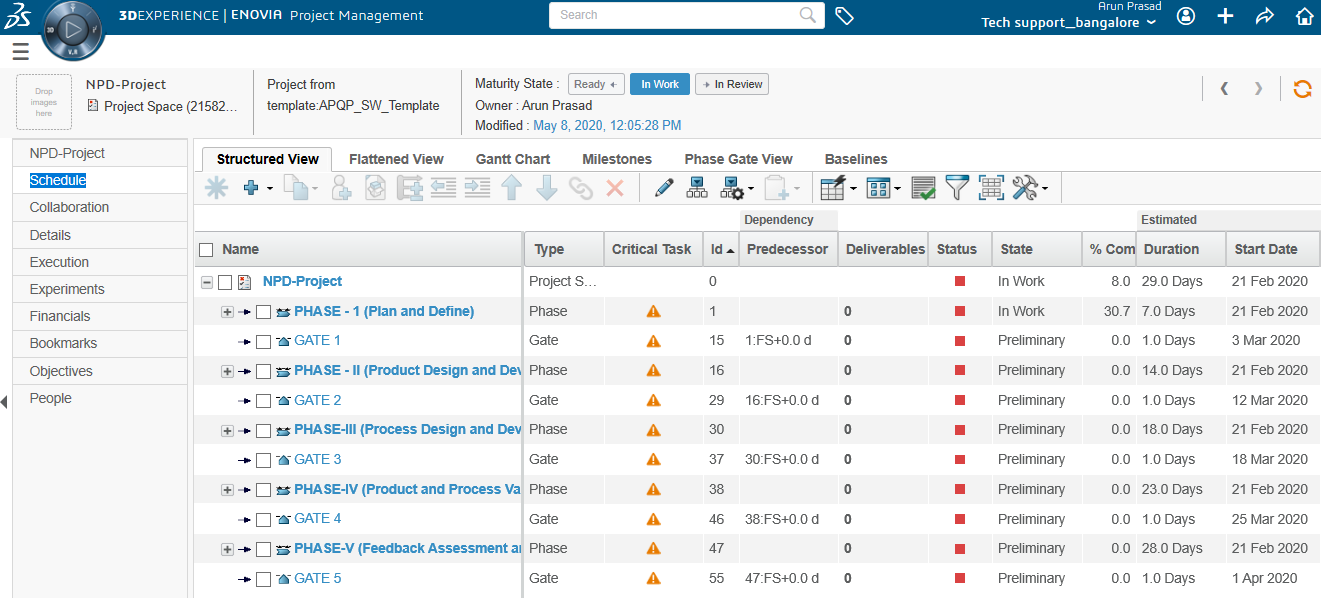

The 5 phases of APQP, from Planning, Product design, Process design, Validation to Product launch is captured as phases with associated tasks & activities with work breakdown structure in 3DEXPERIENCE Program & project management solution thus enabling the CFT members with visibility & traceability across the APQP process, including the status, resource utilization & project management.

The solution helps digitize your processes, track them in real-time, and make improvements based on data.

An example of how APQP is mapped in the 3DEXPERIENCE platform is as shown below,

3DEXPERIENCE has inbuilt tools & utilities (apps) using which the APQP methodologies can be implemented successfully as per needs.

Business Benefits

- By implementing APQP using 3DEXPERIENCE, the company mitigates the risks inherent in introducing or modifying a product.

- Digitize your processes, real-time traceability, and make improvements based on data.

- Eliminate most of the assumptions and risks inherent in the introduction of a new product or the modification of an existing one.

- Improved communication with cross-functional teams/stakeholders including suppliers.

- Improved decision making to work-in-progress tasks and related items such as parts across projects.

- Enhanced product quality and customer satisfaction by leveraging the power of APQP as required utilizing the 3DEXPERIENCE apps.

- Increased knowledge re-use through reviews of previous deliverables such as Failure Modes and Effects Analyses (FMEA), DVP & PQCs, and Control Plans