The COVID-19 pandemic has taken everyone by a surprise right from the large-scale to small scale industries, academic institutions, and other businesses, challenging & disrupting the normality. This rapid outbreak has urged the businesses to shift from on-premises to remote work to ensure their business continuity. Social distancing is needed and to be maintained, business discussions has to be continued as always, more important to collaborate but on a virtual mode. A digital platform is the need of the hour to ensure business continuity and help mitigate the impact of such an unprecedented event or situation.

Dassault Systemes’ 3DEXPERIENCE platform on cloud provides full-fledged solution for every needs of companies of all sizes with a single source of information and applications, everyone on the team can access from home, allowing them to work on their projects collaboratively and efficiently in a safe environment with secured data.

Some of the solutions & services offered by 3DEXPERIENCE platform provides the team with daily work status as if they are at office despite working from home enabling them to address these unprecedented challenges as listed below.

1. Collaborative Business Innovation

This cloud-based collaborative solution delivers the underpinning apps and services that digitally connect all users in the value stream – to establish social communities with consumers and customers to share, experiment, and innovate effectively. Businesses can power their innovation processes with transformative technologies leveraging legacy tools and systems.

Highlights

- Users form social communities to engage in conversations. Users can track all the interactions by reviewing the threaded discussions and can target their responses.

- Cloud-only drives help to securely store documents, allow users to access them from any device, and share documents with co-workers and collaborators across the value chain. To get reviewed with partners, suppliers, and customers, pre-registration is no longer required. Users can send them a link with a simple self-registration where guests can view designs right in a browser and provide valuable feedback. The document sharing experience is greatly enhanced on mobile devices with the 3DDrive mobile app.

- Inbuilt viewers intelligently recognize CAD designs and navigate the hierarchy embedded inside CAD assembly files. Users can share entire assemblies and their peers can not only visualize the design but navigate the entire assembly with ease.

- With Messaging apps, users can instantly engage in 3D collaborative experiences. Users can now augment their 3D collaborative experiences with immersive voice and video.

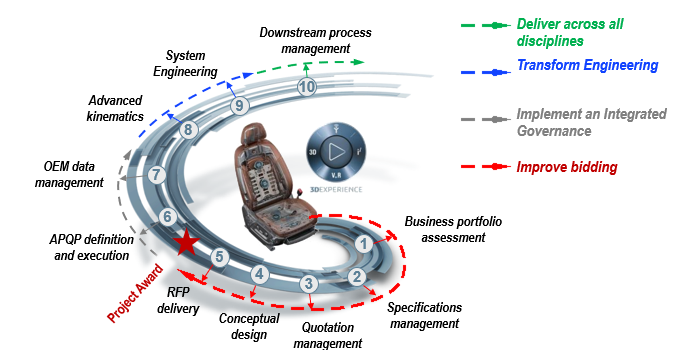

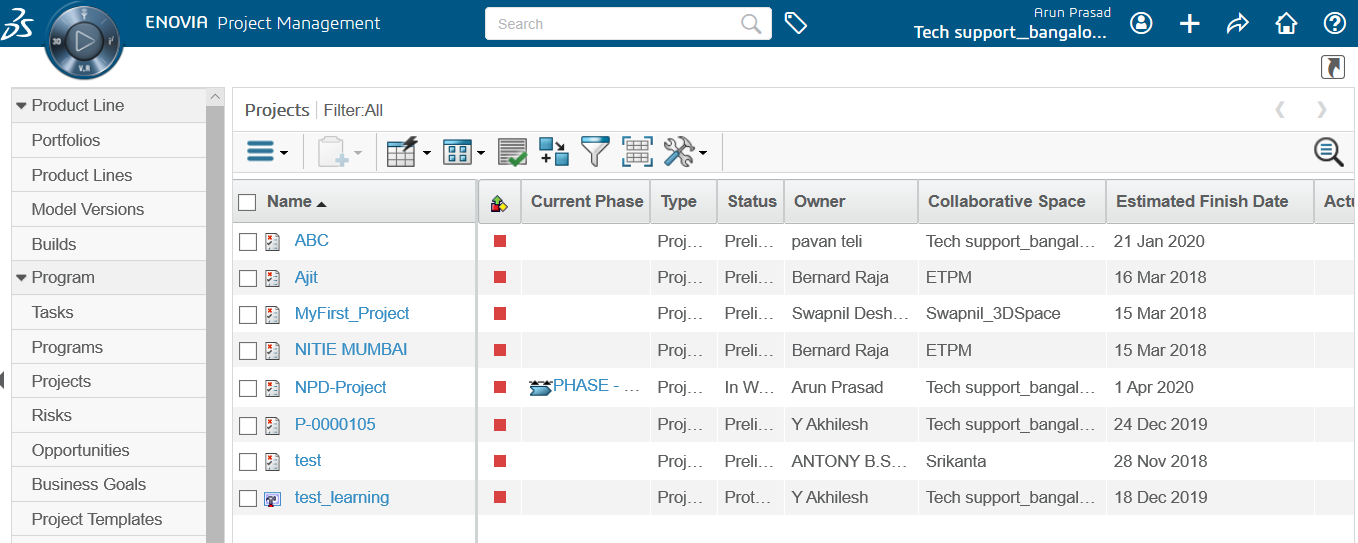

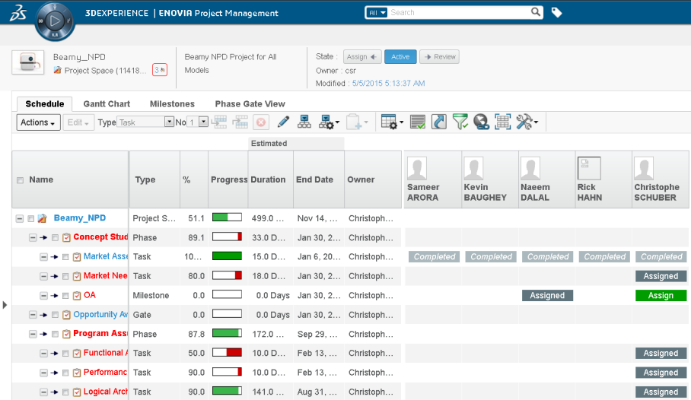

2. Program & Project Management on Cloud

Enables program and project managers to create a competitive advantage by delivering products from concept to market faster. Organizations can concentrate critical resources on the most profitable products while standardizing on best-in-class business processes across the extended enterprise leveraging the below features & functionalities:

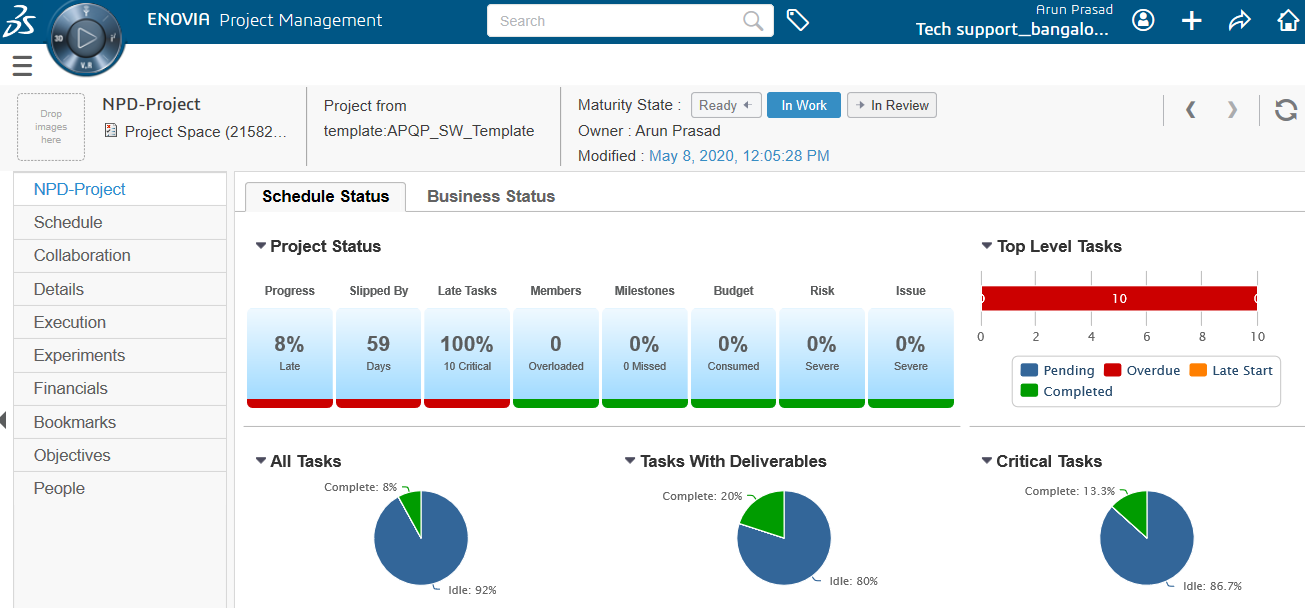

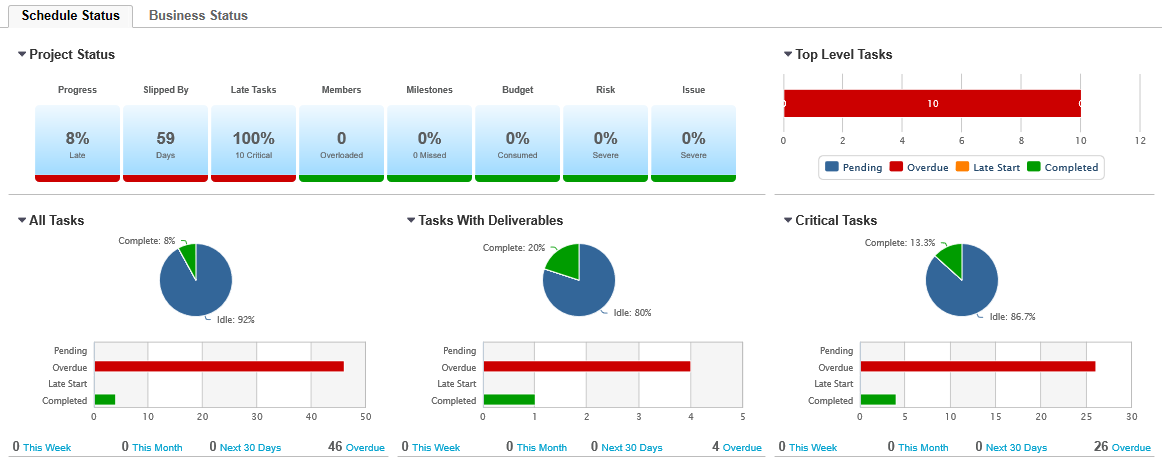

i. Project Dashboards

Dashboards help management with a high-level graphical view of project status by phase, assessments, costs, benefits, issues, and risks.

ii. Project Templates

The repetitive project execution in the organization will help you to develop process standards and improve predictability. The project template contains work breakdown structures (WBS) with more manageable portions, document templates, questionnaires, bookmarks, and folder structures.

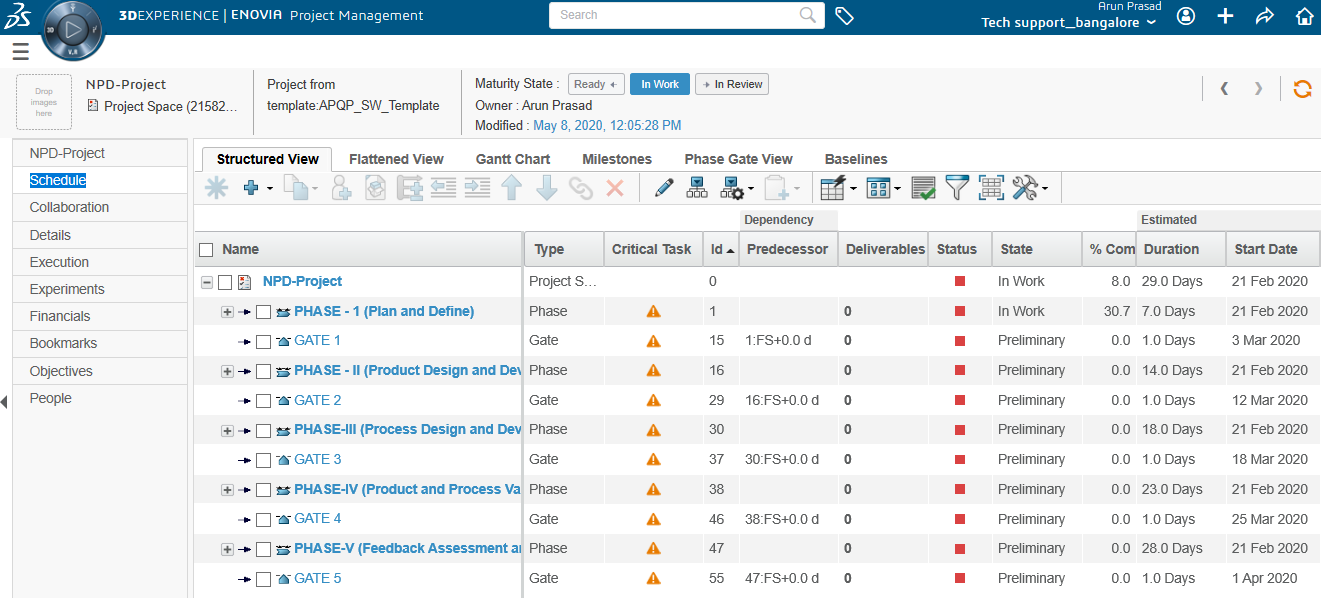

iii. Work Breakdown Structure

Program managers can breakdown the sophisticated product development activities into various manageable subprojects. The project or technical leaders are allowed to assign schedules considering project roles and non-working days, which enables them to define global project teams into phase-gate activities. Project management plays a key role in every phase of the development process from ideation to project delivery and maintenance. When a project is approved, they can update it in the WBS and schedule baselines to make sure that the work is more manageable.

3. Platform of Virtual Factory

The creation and simulation of a 3D digital twin of your factory are efficient through the Virtual Factory platform. You can quickly create the 3D layout models of machines, plants, lines, and work cells leveraging the fundamental library components from a 2D drawing or the cloud generated point from scanning the actual facility. These 3D models help you to analyze the factory flow simulation, visualize & check the machine behavior, and to connect work cells to a PLC.

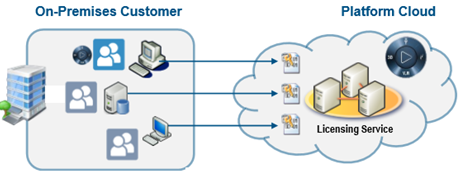

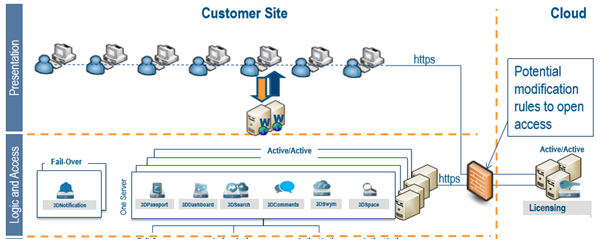

4. Managed licensing services – DSLS On Cloud

The managed licensing service provides you with the ability to run certain levels (essentially, 3DEXPERIENCE) of on-premises DSLS-enabled apps. Using this mode, the specific apps which are enabled to support this mode obtain their license keys from a highly available license server managed by Dassault Systèmes, which is not installed on your premises.