A myriad of products have been changing and improving the facet of our lives, be it machines, vehicles, life sciences. The way products are engineered has been changing recently, being more human-centric. Vehicles are engineered to give optimal driving experience, autonomous vehicles that drive by themselves giving the owner the luxury and comfort, there are many wearable devices being engineered to monitor health etc. To achieve this, a lot of non-destructive testing needs to be done which is achieved very efficiently through virtual simulations. Dassault Systemes’ SIMULIA, a step ahead in virtual analysis, offers the virtual simulation landscape with a variety of simulation and optimisation software like Abaqus, Fe-Safe, I-sight etc. SIMULIA provides a multitude of multidisciplinary, multi-scale simulation applications for various industries such as Aerospace and Defence, Transportation and Mobility, Life-sciences, High tech, Energy and Materials, Industrial Equipment, Heavy engineering etc.

Below are some of the salient features of Abaqus from the SIMULIA portfolio:

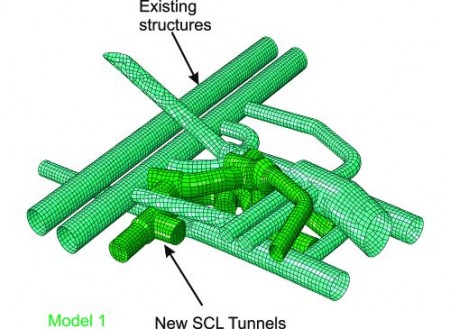

- Abaqus/Standard provides Abaqus analysis technology to solve traditional implicit finite element analysis, including static, dynamic, and thermal analyses, all powered with the widest range of contact and nonlinear material options. Abaqus/Standard also has optional add-on and interface products that address design sensitivity analysis, offshore engineering, and integration with third-party software.

- Abaqus/Explicit provides analysis technology focused on transient dynamics and quasi-static analyses using explicit time integration, which is appropriate in many applications, such as drop tests, crushing, and manufacturing processes.

- Abaqus/CAE provides a complete modelling and visualization environment for Abaqus analysis products. With direct access to CAD models, advanced meshing and visualization, and with an exclusive view towards Abaqus analysis products, Abaqus/CAE is the modelling environment of choice for many Abaqus users.

- Abaqus/CFD provides advanced computational fluid dynamics capabilities with extensive support for pre- and post-processing provided in Abaqus/CAE. These scalable parallel CFD simulation capabilities address a broad range of nonlinear coupled fluid-thermal and fluid-structural problems.

- For implicit and explicit analysis, Abaqus has it all integrated. You can switch from explicit/implicit between analysis steps.

- Abaqus CAE GUI is very user-friendly, and the user can model a problem in a real – virtual manner.

- Abaqus can be used for both linear and non-linear analysis.

to product design, with the goal to optimize user comfort, health and safety, as well as overall system performance. Automotive ergonomics is the study of how an automotive can be designed better for human use.

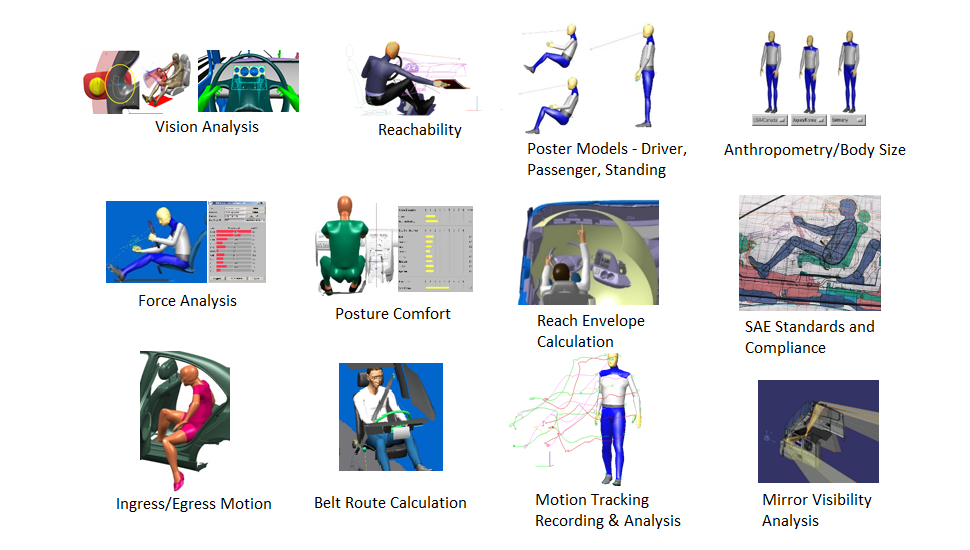

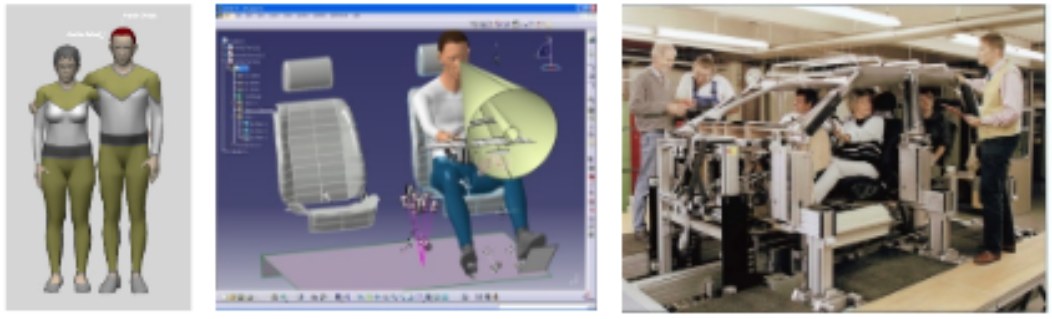

to product design, with the goal to optimize user comfort, health and safety, as well as overall system performance. Automotive ergonomics is the study of how an automotive can be designed better for human use. The use of RAMSIS in the design process increases the ergonomics quality of products and makes ergonomics an integral part of the design process. It allows manufacturers to put the end-user in the center of the development process and build the product that will offer a safe and comfortable environment to the targeted end-user population. From the earliest stage of the design process, until the final layout of the instrument panel, RAMSIS provides the methods, data and information to make well-founded, optimal design decisions from an ergonomic point of view.

The use of RAMSIS in the design process increases the ergonomics quality of products and makes ergonomics an integral part of the design process. It allows manufacturers to put the end-user in the center of the development process and build the product that will offer a safe and comfortable environment to the targeted end-user population. From the earliest stage of the design process, until the final layout of the instrument panel, RAMSIS provides the methods, data and information to make well-founded, optimal design decisions from an ergonomic point of view.